Everyday hollow plastic objects like milk cartons, shampoo bottles, storage drums and watering cans all have a specific manufacturing process in common – blow moulding. The flexible process enables thin-walled, hollow plastic containers to be formed by adding melted thermoplastic to a mould and shaping it as required by blowing compressed air inside. Plastics commonly used in this process include polyethylene, polypropylene, polyethylene-Terephthalate (PET) and polyvinyl chloride (PVC).

What is blow moulding and how does it work?

By LaurensvanLieshout – Own work, CC BY-SA 3.0

It is used to create and join together hollow plastic objects commonly used in packaging and industrial applications such as plastic ducting, tubs and drums. The compressed air component makes the process different from standard injection moulding, which is more commonly used to create solid objects.

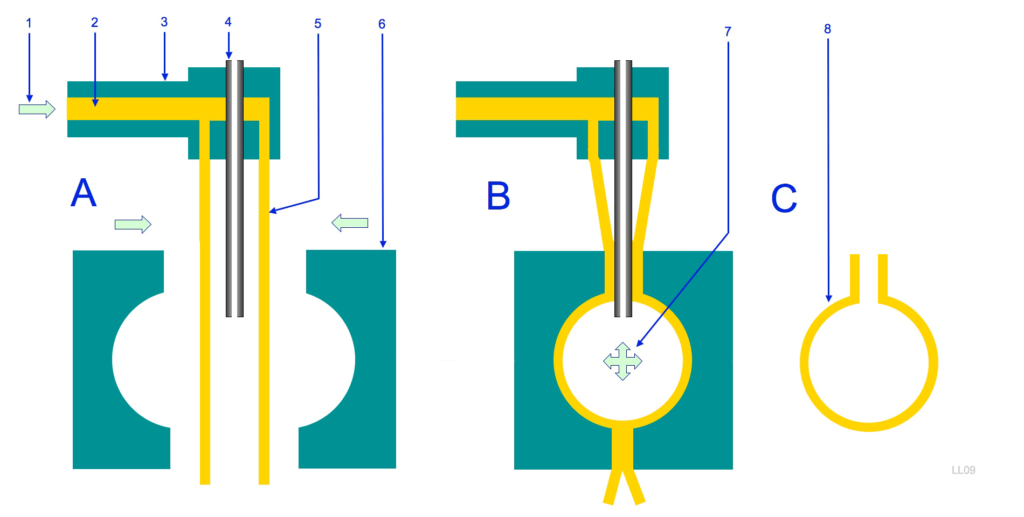

The moulding process step by step starts by forming softened, melted plastic into a tube-like structure using an extruding machine before a hole is made in one end for the compressed air to pass through. This hot plastic tube is called a parison. The parison is then inserted to the mould and clamped into place to allow compressed air to push the plastic outwards, forming the final, hollowed-out shape.

Once the part has hardened, it is ejected from the mould and left to cool. There are three main types of blow moulding. Extrusion blow moulding uses a parison, inserted into the moulding machine and shaped by the plastic being melted to fit the mould and then hollowed out by compressed air. The process is used in around 75% of all blow moulding applications. Injection blow moulding uses a preformed plastic shape instead of a parison, which is supported by a metal core pin and hollowed out by compressed air.

Finally, stretch injection is similar to standard injection blow moulding, but the softened plastic preform is stretched into its final shape before the compressed air is injected to create the hollowed-out end product. Stretch injection blow moulding is particularly suitable for processing PVC and PET products.

What can you make using the blow moulding process?

The huge advantage to the plastic blow moulding process is that the range of products that can be made is extensive. From plastic food containers, shampoo bottles and jars to automotive ducting and industrial tubs and drums, plastic blow moulded products can be found across all areas of domestic and commercial life. As well as within the food and drink packaging sector, blow moulding materials are commonly used to create products for the automotive industry; vehicle fluid storing containers, cooling system components and fuel tanks, for example.

The medical sector relies on the process for spray water bottles and storage containers for sanitising products and medicines, while many household appliances also incorporate blow moulding materials, including reservoirs inside washing machines and dishwashers. Finally, many children’s toys like plastic blocks, dolls and balls owe their existence to plastic blow moulding. Large industrial items are also made using the process, such as plastic tubs and drums, storage tanks and barrels for transporting liquids.

What are the blow moulding advantages and disadvantages?

Just like any other plastic manufacturing process, blow moulding comes with both advantages and disadvantages. Extrusion blow moulding can be highly versatile, producing irregular and highly bespoke shapes, curves and wall thicknesses. Finished products contain fewer stresses and the tooling and production costs can be lower overall. Disadvantages include limited wall thickness control and the fact that products are much harder to recycle.

Components such as handles can be harder to attach, so they need to be incorporated into the mould for maximum efficacy. Meanwhile, injection and stretch injection blow moulding offer benefits such as the ability to create bespoke wall thicknesses, enabling parts such as bottlenecks of different shapes to be formed more accurately. The processes don’t leave seams on the bottom of finished products, making them more aesthetically pleasing and robust.

However, the use of preformed plastic shapes means that production costs will rise, as there will be increased change-over costs from one plastic part to another and an increased number of moulds and core pins needed. There is also a stricter size limitation on parts that can be made by these injection-based processes.